The Uses and Benefits of Rope Splicing Onboard a Yacht

Traditional sailing skills of rope splicing and whipping are ones that some boat owners may know and appreciate. But for those unfamiliar with these techniques, this informative article may help you better understand the onboard benefits of these sailmaking arts.

Published 2 years ago

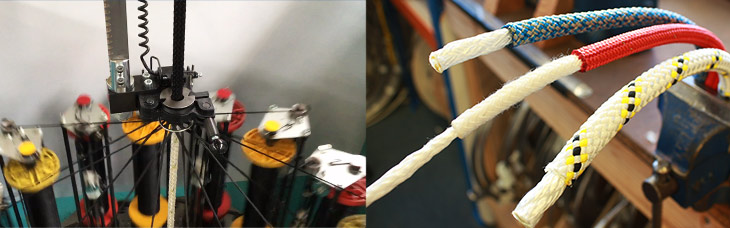

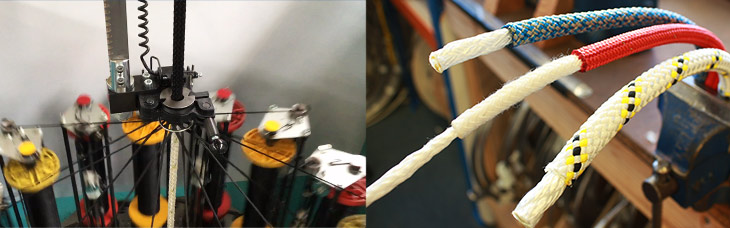

The Rope Manufacturing Process and How it Affects Splicing

Understanding the rope manufacturing process is fundamental to producing a proficient splice.

All ropes start life as yarn drawn out into long individual fibre filaments, which are wound together to form twines.

The twines are then woven together to produce strands. At each step, the twisting process can be alternated between clockwise and anticlockwise to achieve the optimum balanced structure. The direction of rotation is commonly known as left and right-hand lay, but technically in the initial stages, the opposing twists are defined as S and Z fibres.

Equal quantities of opposing lay strands are interwoven from individual spools to create a balanced braid, also known as a plait. The number of spools on the rope manufacturing machine dictates the number of plaits in the finished braided rope. The most common configurations are 8, 12, 16, 24 and 32plait.

Rope manufacturers use precision engineering design skills to set up their technological spinning machinery. The challenge is accurately achieving the designed breaking strain, stretch, creep and abrasion resistance. The key to success is controlling the precise application of twist and tension to the correct fibre volume.

Splicing can’t be Mechanised

Machinery can only effectively ensure the desired characteristics of a rope by manufacturing in continuous lengths. A machine can’t maintain the rope’s structural integrity and tension while simultaneously braiding back into itself.

Therefore, the only way to create a splice is to cut the line, create free ends in the strands or braids and work them back into the rope by hand.

The Complex Nature of Rope Construction makes Splicing an Art Form

Understanding the complex relationship between the tension, the twist, and the lay is essential to producing an effective splice. In addition, adapting the process to account for the subtle variations in rope design used by different rope manufacturers constitutes the cornerstone of a professional rigger’s skill. All ropes, even the best quality, will have flaws or foibles that only training and experience can counter.

A good splice should be worked and tapered back into the standing part of the line with a similar tension and matching lay to distribute the load evenly. For a three-strand loop splice, the interweaving strands should correlate with the original lay angle and tension.

For double braid splicing, the cover-to-core ratios, the number of plaits and the degree of tension vary according to the rope diameter and the manufacturer, requiring adjustment to suit.

Rope manufacturers make the production process as continuous as possible by using the longest practicable lengths of filaments and twines and staggering any joins to minimise disruption and guarantee the line’s performance.

Professional riggers can spot any ropemakers’ joins (tiny little knots) and any other inconsistencies or idiosyncrasies early in the process and make the necessary adjustments to guarantee consistently strong and reliable rope splices.

The Most Common Uses for a Splice

Splicing encompasses the skilful art of separating the strands for the last section of a rope and dexterously reintegrating them by a specific interweaving method to create a loop or eye of any size, thus avoiding the use of a knot.

The finished loop can be used to attach the rope to, e.g. a mooring cleat, the tack, head or clew of a sail, a block or a deck fitting, and the loop size can be adjusted in the splicing process accordingly.

A teardrop-shaped thimble can be inserted into the loop for applications where high load capacity and abrasion resistance are critical factors.

A Splice can also be applied to connect the end of an anchor warp to an anchor chain, creating a dependable windlass-friendly joint or to join two ends of the same rope to create an endless loop.

The Advantages of a Splice

- Permanence and Endurance

A proficient splice is far more reliable than a knot, making it preferable for mooring, anchoring, and rigging applications. In addition, applying a competent stitching and whipping will reinforce the security of the splice and give you peace of mind when the weather deteriorates.

A neatly finished splice is a compact, streamlined termination, lowering the risk of snagging and abrasion and consequently prolonging the natural working life of both the splice and the rope.

- Strength

Spliced rope loops make a much stronger attachment than any knot. Depending on the fibre and the construction of the rope, a professionally executed and finished splice will maintain between 85% and 100% of the manufacturer-rated breaking load.

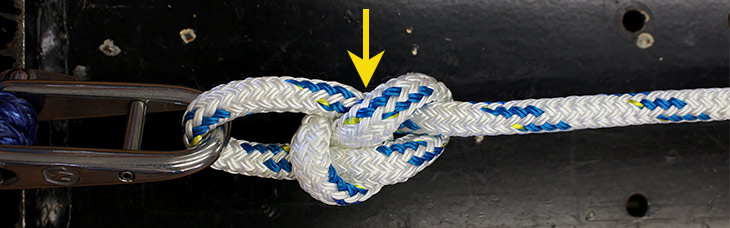

By contrast, knots can reduce the breaking load of a rope by up to half the manufacturer rating. To make matters worse, the reduction is most severe in knots which feature one part of the line pinching across another part at right angles to the loaded line.

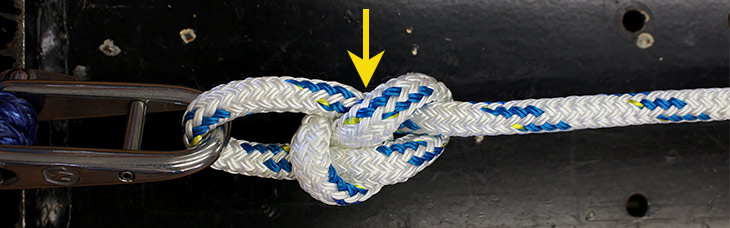

As the load increases, the transverse pressure cutting across the rope escalates, causing stress failure in the fibres. Unfortunately, the bowline is one of the worst examples of strength loss, but also one of the most common methods of creating a loop onboard, illustrated below:

Looking at it the other way around, a larger diameter of the same rope made off with a knot will be required to attain the same strength as a smaller diameter rope finished with a proficient splice. Increasing the diameter of the rope will make the line more expensive, and there is also a potential double whammy on the cost. Some of your fittings, e.g. winches, blocks, fairleads and clutches, may need upgrading to make them compatible with the larger rope.

- Handling and Management

Splices are less bulky and more friendly to crew hands than knots making lines more straightforward to attach and disengage.

Also, as mentioned in the paragraph above, the line diameter may need to be greater than the optimum handling size for that application.

In addition, the ergonomic, user-friendly aspects of a spliced line improve efficiency. Onboard manoeuvres, especially those which entail a great deal of line management duties, will be much more enjoyable for your crew, especially those who are relatively inexperienced.

- Substance and Style Appeal

Splicing is an art form requiring unique skills and techniques gained through training and diligent practice. An accomplished, spliced and whipped finish to all the ropes onboard will impart an understandable sense of pride and satisfaction in a shipshape job.

Neat and tidy spliced lines promote an orderly aura of safety and efficiency which will be the envy of other yacht skippers and crew and possibly their inspiration too. The shipshape effect can transform all your lines, whether they are mooring warps, anchor warps, sheets, halyards, control lines, or simply your fender lanyards.

So, is there a valid argument (or excuse) for not splicing the ends of your ropes?

There is only one good reason and that is when you do not need a loop on the end of the line for attachment.

If that is the case, a stitch and whip will be far and away the best method of sealing and securing the end of the rope.

Stitching and Whipping

Stitching and whipping the end of a rope is the best alternative to a splice because it binds all the strands together and prevents the end from fraying. A stitched and whipped end is advisable when passing the line through cleats, jammers, and clutches or making it off around cleats.

Stitching and Whipping is the optimum solution for these applications:

- When Making the Rope off on a Mooring Cleat

Taking turns around a deck cleat or strongpoint, using a figure of eight configuration, is commonly called ‘making off’. This solution is reasonably quick, adjustable, and perfectly acceptable if executed proficiently. Even several hurried wraps may suffice as a temporary measure.

- When Passing the End through a Jammer or Clutch

Jammers (also known as jamming cleats) and Clutches provide the means to hold or release a rope, making them more conveniently adjustable than an ordinary cleat.

Jammers can have open jaws, allowing rapid redistribution. Clutches and some jamming cleats are captive, requiring the line to be reeved through, making them a more permanent arrangement.

The other reasons for not splicing come down to Expedience, Opportunity, Physical Ability, Confidence, and Expense.

- Expedience essentially means tying a knot

Knots and hitches are a good stopgap solution. If you know your knots, they can be quick to produce, even under pressure.

- However, Knots have some Major Disadvantages:

- Knots are bulky, making them awkward and cumbersome to handle, especially when passing the end through a tight space.

- Knots may be considered unsightly or unseemly onboard a ‘tight ship’.

- Knots can slip or come undone accidentally, which may prove problematic or potentially disastrous.

- Knots, even those tied correctly, cause a major loss of strength in the rope, whereas a skilfully executed splice can be nearly as strong as the rope.

- Knots which involve one rope passing across the other at right angles can reduce the breaking load of the rope by up to 50%

- The knock-on effect is that you may need a larger diameter rope to achieve the desired strength leading to extra cost.

- Opportunity – do you have the time and inclination?

Manufacturers have made huge advances in rope technology in recent years, resulting in a proliferation of multiple different fibres and constructions. Splices have been developed to suit all the variations, and the time and effort to learn them all may not be practical.

When it comes to splicing rope work, practice makes perfect, which may take patience and perseverance, not to mention paying for and sacrificing a significant amount of line. Every splice demands a particular process and specific techniques to attain a neat, strong, and reliable finish. The finer arts, or ‘tricks of the trade’, are not always detectable on video tutorials either. All this may explain why knots are so popular.

- Potential Aches and Pains

Splicing can be physically exacting. Professional riggers have seasoned hands combining a firm grip, deft touch, and sturdy fingers and they may also have the luxury of a varied order book to mix up their workload. Achieving the necessary strength and reliability will probably take persistence, but recurring actions may lead to painful wrists, hands, and fingers through repetitive strain.

- Confidence in your Ability

Trusting your splicing, especially for critical applications, will be paramount. A bodged splice could fail with dire consequences. If you are uncertain about your ability, don’t take the risk. Instead, stick to what you know and enlist the services of a professional rigger.

- Expense

The extra cost of all the splicing on top of the price of the ropes might smash the budget. Even so., it may still be wise to have a rigger provide the professional finish in the key areas. The good news is that getting an instant quote online is ever so simple and accessible anywhere with Wi-Fi or 4g in this high-tech internet world. If you can’t justify the cost for all the splices, you can always augment the professional work with some DIY efforts for less crucial applications. Let’s face it, losing a fender isn’t nearly as catastrophic as your yacht coming adrift from a mooring.

Ten Top Benefits of Splicing Your Yacht Ropes

- Maximum strength

- Dependable security

- Long-lasting solution

- Excellent wear and tear resistance

- Compact snag-free profile

- Ergonomic handling

- Crewing efficiency

- Ultimate load-bearing capability (hard eyes)

- A feeling of pride in a shipshape finish

- Splicing is readily accessible to order with your ropes online.

…………………………

About the Author:

Jimmy Green Marine is a family business owned and run by the Green family, based in the coastal fishing village of Beer in East Devon in the UK. The company started out as Mail Order Chandlers in 1981 and has continually evolved since those early days attending Boat Shows and Boat Jumbles.

Four decades of exporting experience combined with an intuitive website shipping calculator means that you can have your order delivered to your home, business or direct to your yacht anywhere worldwide.

Their flagship, innovative Custom Build website system provides an instant quote for all your professionally spliced and finished wire and rope rigging, mooring and anchoring solutions.

You can access this online from wherever you can get an internet connection, however remote.

…………………………

Related Links:

- About Jimmy Green Marine

- Custom Splicing, Rigging and Sewing Service

- Worldwide Shipping

- Jimmy Green Marine joins Noonsite.com as Official Ropes and Rigging Partner (April 2023)

Other Articles for Noonsite:

- How to Choose a New Halyard (July 2023)

- How to Choose Your Next Anchor Chain (August 2023)

- Ten Reasons to Stitch and Whip Your Ropes (September 2023)

- When to Replace your Standing Rigging (October 2023)

………………………………

The opinions expressed in this article are the author’s own and do not reflect the view of Noonsite.com or World Cruising Club.

………………………………

Find out all news, reports, links and comments posted on Noonsite, plus cruising information from around the world, by subscribing to our FREE monthly newsletter. Go to https://www.noonsite.com/newsletter/.

Related to the following Cruising Resources: Equipment, General, Global Yachting Services, Sails & Rigging